This weekend, I went outside and started my engines.

You see, small gasoline engines need to be run from time to time. Think of it as exercising the engine. Not only does regular use keep the carburetor functioning smoothly, it helps prevents rubber parts from drying out and promotes smooth starting when you need your tool to work.

This is especially important for seasonal tools, like lawnmowers, rototillers, and garden tractors, which you might only use a few months per year. For preppers, generators may be even more critical. That’s something you want to start with one pull when you need it.

In our case, the biggest problem child was the garden tractor. First, I had to pump up a flat tire, something I need to do about every six weeks during the season, and then charge the battery. Those are easy fixes, and once done, the engine caught and ran just fine. I drove it around the house and parked it. We don’t need to mow the grass yet (it’s a stretch to call it a lawn), but it’s ready for when we do. And with 19 hours until its next oil change, I may even make it through the summer without changing the oil.

The generator started up on the first pull and ran smoothly. For a load, I attached the air compressor, which it handed easily. (It’s always good to test your generator under a load.)

The chain saw and weed whacker both took a couple of extra pulls to start. The chainsaw settled in and ran fine. I cut three logs and decided I must have sharpened the chain before I put it away for the winter. (Nice!) The weed whacker idled a little fast, but that’s better than too slow. I’ll see if it settles down after its first heavy use. If not, I’ll watch some videos and see what, if anything, needs to be done.

We run the log splitter frequently enough that I didn’t need to start it, but it is due to have its oil changed soon.

The Fuel System

The fuel system in a small engine may seem pretty simple, but there are numerous things that can go wrong, resulting in an engine that either won’t start or may start but won’t run well or dies when it should idle. Problems often start in the gas tank. After a long winter, there can be water in your machine’s gas tank, sometimes caused by condensation. To avoid this, you can store your tool with an empty gas tank. If it’s too late to do that, just pour out the old gas and add fresh gasoline. Ethanol-free gas is best for small engines. I rotate my gas cans at least once year. I then label them with a Sharpie so I know how old the gas is.

While your gas tank is empty, look inside and make sure there’s not any grit or dirt in the tank. If there is, you can try rinsing the tank and dumping it out, but using a turkey-baster type tool that allows you to suck up the dirt or sand with some fuel may be your best bet.

While you are examining the empty tank, look at the fuel filter. These are inexpensive and easy to replace. Gas lines may also dry out and break, especially if an engine has been sitting unused for years. When I need to replace a dry, cracked fuel line, I buy it by the foot at the local auto parts store. Just make sure you know the inner diameter.

That brings us to the carburetor, priming bulb and choke, which are responsible for feeding just enough gas and air to the engine to get it to start, warm up, and run. (Close the choke to start a cold engine and then open it up as the engine warms up.) I will not go into detail about repairing carburetors because it would triple the length of this post. What you need to know is a dry carb in a two-stroke engine may require you to rev and run the engine for several minutes several times over several days before the diaphragms loosen up and allow the engine to run with no hiccups. So if your chainsaw sat unused for six months, it may need this kind of extended break-in period to return to its normal smooth running self.

How to Store your Device

If I am planning to use a machine again in a month, I don’t worry about how I store it. Storing it for the off-season is a different story and I prefer to store it with an empty gas tank. When I mow the lawn for the last time in the fall, I let the garden tractor run until it runs out of gas. Then I try to restart it two or three times to make sure there’s no gas left in the carburetor that could gum things up.

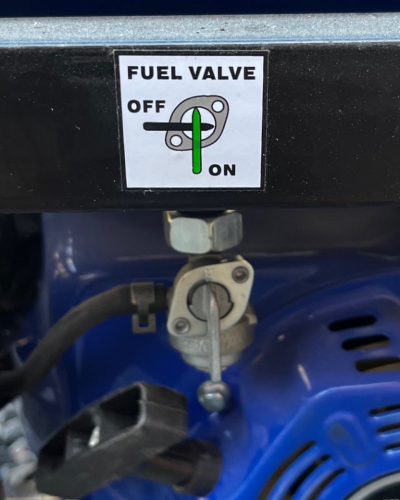

Both the generator and the log splitter have a gas-tank cut-off switch, which I find very convenient. This allows me to shut off the gasoline and allow the engine to run out of gas without requiring an empty tank. It’s a perfect way to store your engine when you aren’t sure when you will use it again. It doesn’t address the water-in-the-gas issue, but it does help protect your carburetor.

When you use the on/off switch on a small engine, it usually grounds out the spark, meaning there is no way to combust the fuel in the chamber. That works great if you are shutting the machine down for a few minutes or a few days. If you’re shutting it down for a few weeks or months, I recommend using the gas-tank cutoff switch instead and letting the engine run until it sputters to a stop.

Oil and Grease

I expect most people to know this, but let’s review to be safe: Two-stroke engines use gasoline blended with oil. Sometimes called pre-mix I store mine in 1 or 2.5-gallon cans labeled “saw gas.” Two-stroke engines are small but loud and can be found on most chain saws, weed trimmers and similar equipment.

If your device has a separate oil tank and oil filter, then it’s a four-stroke engine, and you will need to change the oil according to the manufacturer’s recommendation. Don’t use “saw gas” or gas with oil in it in your four-stroke engines. Larger machines often have hour meters and the owner’s manual will tell you when to change the oil, including the all-important first oil change. I like to have oil and at least one spare filter on hand for each device.

Besides our garden tractor, the log splitter needs to have its oil changed. It also has hydraulic fluid, which should be checked and topped off during spring maintenance.

Small gasoline-powered devices may not have grease fittings, but larger ones probably do, especially in joints, axels, and other areas where metal parts might wear against each other. So look for those grease nipples and use a grease gun to apply grease as needed.

Because I have a small homestead, I don’t have any diesel powered engines. Everything I run uses gasoline with no ethanol added. I’d love to get a diesel generator, but even the used ones are expensive. For now, I stick to gas, which reduces the number of fuels I need to store. From a prepping standpoint, diesel has advantages. While it is flammable, it is lacks the explosive power of gasoline. That makes it easier to store and you can legally keep more of it on hand.

Power Tools

I grew up using a hammer, screw driver, and shovel, but for big jobs, I prefer a nail gun, power driver, and rototiller or back hoe. Power tools make us more efficient. So protect your investment and treat your small engines right. Hose off the dirt, grass, and grime to keep your equipment clean. Service them regularly, especially oil and grease. Check your belts and chains. And don’t forget to listen. If you are attuned to how an engine sounds, you can often hear a problem in time to address it before it becomes an expensive repair.

When the SHTF, many tasks will require manual labor. The more assistance you can get from your small engines, the faster and easier you will get the work done. While I won’t worry too much about trimming weeds after TEOTWAWKI, I do plan to use my chainsaw and log splitter. he older I get, the more we’ll need them.

Keep your devices in good working order, store plenty of fuel, and cross your fingers.